You may wonder what coming out from two towers in this picture?? Relax..It's nothing but just H2O!!! Welcome to our blog!! As nuclear power ambassadors, our mission is to raise your awareness on nuclear as green energy. "Nuclear" seems a big deal to you?..Well, it's not..Once you understand it, you'll love it. We promise!!!

Pages

FOR A BETTER WORLD

THINK CLEAN!THINK GREEN!THINK NUCLEAR!

Friday, October 29, 2010

Here we are

Thursday, October 28, 2010

Additional info on Safety Details of a NPP

Saturday, October 23, 2010

Course summary

"Nuke is our friend " videoclip republish

http://www.youtube.com/watch?v=FXMz_4K_M2Y

Wednesday, October 20, 2010

Further discussion on THINK GREEN BECAUSE NUCLEAR IS GREEN!

Ronald Reagan

Almost every way we make electricity today, except for the emerging renewables and nuclear, puts out CO2. And so, what we're going to have to do at a global scale, is create a new system. And so, we need energy miracles.

Bill Gates

Tuesday, October 19, 2010

THINK GREEN BECAUSE NUCLEAR IS GREEN!

- One of them would be, it doesn't emit any green house gases like carbon dioside and sulfur hexafluoride.

- It is also clean because it doesn't occupy much area compared to hydro power plant, where massive area needed to built a damn for a hydro power plant (can see how much of habitat will be in jeopardy if we change the structure of the original surroundings)

- NPP only consumes 3 tonnes of uranium per year, while coal powered plants uses 3 million tonnes of coal. (don't you see how much area will be used to operate for mining purposes and also the amount of energy used to transport them?

- it is green because the fuel, uranium can be recycled (can we do that for coal based power plants?)

- fuel of uranium costs mush more lower than the amount that our country spents for importing fossil fuels and coals

- operating a NPP creates various kind of job oppurtunity in the job market and at vasities, where we can offer courses related to nuclear technology

- who knows one day, we can even develop our own type of NPP and built it around the world

Sunday, October 17, 2010

"Nuke is our friend " videoclip

Please set FULL SCREEN to enjoy it!!!

http://www.youtube.com/watch?v=FXMz_4K_M2Y

Wednesday, October 13, 2010

URANIUM AS NUCLEAR FUEL SOURCE

Uranium Is Abundantly Found in Nature but Must be Processed into Fuel.

Most of Our Uranium Is Imported

- 14% of delivered uranium came from the United States

- 86% of delivered uranium was of foreign-origin:

- 42% was from Australia and Canada

- 33% originated in Kazakhstan, Russia and Uzbekistan

- 11% came from Brazil, Czech Republic, Namibia, Niger, South Africa, and the United Kingdom

Enrichment

Because less than one percent of uranium ore contains uranium-235, the form used for energy production, uranium must be processed to increase the concentration of uranium-235. This process—called enrichment—increases the percentage of uranium-235 from one to five percent.

It typically takes place at a gaseous diffusion plant where the uranium hexafluoride is pumped through filters that contain very tiny holes. Because uranium-235 has three fewer neutrons and is one percent lighter than uranium-238, it moves through the holes more easily than uranium-238. This method increases the percentage of uranium-235 as the gas passes through thousands of filters.

Fuel Fabrication

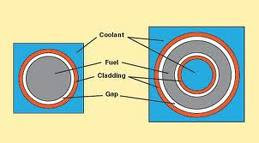

Fuel FabricationThe enriched uranium is taken to a fuel fabrication plant where it is prepared for the nuclear reactor. Here, the uranium is made into a solid ceramic material and formed into small barrel-shaped pellets. These ceramic fuel pellets can withstand very high temperatures, just like the ceramic tiles on the space shuttle. Fuel pellets are about the size of your fingertip, yet each one can produce as much energy as 150 gallons of oil. The pellets are sealed in 12-foot metal tubes called fuel rods. Finally, the fuel rods are bundled into groups called fuel assemblies.

Uranium Fuel Cycle:

Nuclear Reactor

The uranium fuel is now ready for use in a nuclear reactor. Fissioning takes place in the reactor core. Surrounding the core of the reactor is a shell called the reactor pressure vessel. To prevent heat or radiation leaks, the reactor core and the vessel are housed in an airtight containment building made of steel and concrete several feet thick. The reactor core houses about 200 fuel assemblies. Spaced between the fuel assemblies are movable control rods. Control rods absorb neutrons and slow down the nuclear reaction. Water also flows through the fuel assemblies and control rods to remove some of the heat from the chain reaction. The nuclear reaction generates heat energy just as burning coal or oil generates heat energy. Likewise, the heat is used to boil water into steam that turns a turbine generator to produce electricity. Afterward, the steam is condensed back into water and cooled. Some plants use a local body of water for cooling; others use a structure at the power plant called cooling towers.

Like most industries, nuclear power plants produce waste. One of the main concerns about nuclear power plants is not the amount of waste created, which is quite small compared to other industries, but the radioactivity of some of that waste. The fission process creates radioactive waste products. After about three cycles, these waste products build up in the fuel rods, making the chain reaction more difficult. Utility companies generally replace one-third of the fuel rods every 12 to 18 months to keep power plants in continuous operation. The fuel that is taken out of the reactor is called used fuel. The used fuel contains both radioactive waste products and unused fuel. The used fuel is usually stored near the reactor in a deep pool of water called the used fuel pool. The used fuel cools and loses most of its radioactivity through radioactive decay. In three months, the used fuel will lose 50 percent of its radiation; in one year, 80 percent; in 10 years, 90 percent. The used fuel pool was intended as a temporary method for storing used nuclear fuel.

However, there is no permanent storage solution yet for used nuclear fuel, and fuel pools space is running out. The nuclear industry has designed dry cask storage as another temporary solution. Now, the used fuel stays in the pool for five to seven years. Then, it is moved elsewhere on the nuclear power plant site to be stored in vaults or dry casks. Each of these methods for managing used nuclear fuel puts the fuel into airtight, steel and concrete structures. The U.S. Nuclear Regulatory Commission has stated that it is safe to store used fuel on site for at least 120 years. Eventually, the used fuel will be reprocessed and/or transported to a permanent federal disposal site.

Image of an used fuel storage pool

Reprocessing

Used fuel contains both radioactive waste products and unused nuclear fuel. In fact, about one-third of the nuclear fuel remains unused when the fuel rod must be replaced. Reprocessing separates the unused nuclear fuel from the waste products so that it can be used in a reactor again.Currently, American nuclear power plants store the used fuel in used fuel pools—without reprocessing. Reprocessing is more expensive than making new fuel from uranium ore. If uranium prices rise significantly or storage becomes a bigger problem, reprocessing may gain favor.

Tuesday, October 12, 2010

GREEN LECTURE SERIES SUMMARY PART 2

Monday, October 11, 2010

GREEN LECTURE SERIES SUMMARY - PART 1

Sunday, October 10, 2010

Suggested reactors for Malaysia.

|

| Courtesy of TNB Nuclear Energy Unit |

Types of reactor Part 2

|

| Summary of Nuclear Reactor Evolution. Courtesy of Argonne National Laboratory |

Wednesday, October 6, 2010

Types of Reactor Part 1

|

| COURTESY OF NRC USA |

|

| COURTESY OF NUCLEAR WORLD.ORG |

Type 2:

|

| COURTESY OF NRC USA |

|

| COURTESY OF NUCLEAR WORLD.ORG |

Type 3:

|

| COURTESY OF NULEAR-WORLD.ORG |

Type 4:

|

| COURTESY OF NUCLEAR-WORLD.ORG |

Type 4:

Xe Poisoning Effect

Tuesday, October 5, 2010

The Axe-Man of Nuclear Reactor

The story begins with a well. It is called the well of electricity. By some means, it produces electricity from inside and it is very very hot (hundreds of degree)!! There is some kind of rods hung above the well, suspended by a rope. There is a person in charge of this well. His job is to take a fire axe, waiting for the signal. When the ringing bell informs that the well temperature is over the limit, he rapidly cuts the rope, allowing the rods to fall into the well and stop whatever happening in it. As for his good job, he is given a title as SCRAM, or Safety Control Rod Axe Man.

Who is he?

Well, the Axe man is nobody but control rods of nuclear reactor. They are made by neutron-absorbing materials such as Silver (Ag), Indium (In), Cadmium (Cd), Hafnium (Hf) or Boron (B). Their function is to increase or decrease the number of neutrons in the reactor. They are inserted or withdrawn from the core to control the rate of fission reaction (depending on the number of neutrons). In turn, it affects the thermal power of the reactor, the amount of steam produced, and hence the amount of electricity generated.

If the materials absorb all the neutrons coming to them, they are called “Black” neutron-absorbers. If only part of incident neutrons is absorbed, they are called “Grey” neutron absorbers. It is like we tend to absorb a larger amount of sun lights when wearing black clothes than white clothes (simple enough??)

Control rods can operate to serve different purposes. Therefore, they are called different names.

1. Shim rods: To make a coarse adjustment in the reactivity of a nuclear reactor

2. Regulating rods: To make a fine, small adjustment to maintain desired power

3. Safety rods: To provide a very fast shutdown in case of unsafe condition (SCRAM).

Different type of reactors and controls require different type of control rods. They are often combined together to become dual-purpose or triple – purpose rods.

Beside the control rods which control the reactivity of nuclear reactor, another important element which contributes in this job is called Poison.

Although it is called poison but it is good for the nuclear reactor. It is also made of neutron-absorbing materials like control rods. The need of Poisons is explained as following.

After a long time operation, the amount of fuel contained in the core decreases. Therefore, the fuel in excess of that needed must be added when the reactor is built. However, to maintain the normal operation of reactor, we need to decrease the amount of excess power which is generated from excess fuel loaded into the core. One method is to use movable control rods as described above. But control rods alone to balance the excess reactivity may be impractical for a particular core design as there may be insufficient room for the rods or large their mechanisms. That’s why to control a large amount of excess fuel without adding additional control rods. So, we need Poisons.

There are several types of Poisons.

1. Burnable poisons: as their names, they are burned up when absorb neutrons. So, its effect is decreasing over the core life.

2. Fixed burnable poisons: they are burnable poisons which are shaped with the core.

3. Soluble poisons: they are soluble circulated in the coolant during normal operation.